ITA Expertise

Centre for High Performance Materials (CFM)

Innovative fibre reinforced materials offer unique properties and are therefore of interest for manifold applications. They are used in automotive and aerospace applications, but also in medical products, industrial and building applications. Especially for small and medium enterprises (SME) there is a large gap to overcome between the development of innovative fibre based materials on lab- or pilot-scale and the implementation in practically applicable solutions. The basic approach to transfer knowledge from research to the industry consists of three steps:

New and modified polymers or precursor and nano-structured additives enable the development of functionalized fibres with innovative properties.

New and modified polymers or precursor and nano-structured additives enable the development of functionalized fibres with innovative properties.- In combination with new types of matrix materials tailored composite materials can be designed. This includes the modelling and manufacturing of complex 3D-shaped textile preforms and the subsequent consolidation to specimens and parts and the (non-destructive) testing.

- The crucial step to sustainable innovation is the (partially computer-aided) up-scaling of the research findings to an industrial scale. This requires detailed knowledge of the scientific fundamentals of the new materials, their production processes on the one hand and

the technological and economical boundary conditions for an industrial production on the other hand. This transfer of knowledge can only be achieved by a close cooperation between research facilities and companies.

the technological and economical boundary conditions for an industrial production on the other hand. This transfer of knowledge can only be achieved by a close cooperation between research facilities and companies.

A close look at the high performance fibre materials technology portfolio of North Rhine-Westphalia (NRW) reveals a gap in the infrastructure to overcome the obstacles for up-scaling. This gap is closed by the “Centre for High Performance Fibre Materials” (CFM) under the supervision of Priv.-Doz. Dr.-Ing. Dipl.-Wirt.-Ing. Gunnar Seide.

The CFM is affiliated to the Institut für Textiltechnik (ITA) der RWTH Aachen University and sees itself as a centre of competence especially for SME in NRW and has three thematic focuses in order to transfer the knowledge from research to the industry:

- Development of innovative high-performance fibres and their production on a pilot scale

- Modelling, production and testing of complex 3-dimensional textiles and composites

- Up-scaling, know-how transfer, education and training

The CFM is integrated in the scientific excellent, interdisciplinary and industry orientated research environment of the RWTH Aachen University. Here it is worth pointing out the research networks “aachen polymer chain: apc“, „Aachen Composites Engineers: ACES“, the Materials Forum of the RWTH Aachen University and the Life Sciences Forum. Furthermore, ITA, as one of the initiator of the project, is member of the “Zukunftsintitiative Textil NRW” (ZITEX), “Kunststoffland NRW” and two excellence clusters (“Integrative Production Technology for High-Wage Countries” and “Ultra-High-Speed Mobile Information and Communication”).

_______________________________________________________________________________________________________

ITA-Preformcenter: Research and development platform for the production of textile preforms for fibre reinforced components

There are numerous process possibilities for the manufacturing of fibre-reinforced plastic components (FRP). The selection of a process is determined by the geometrical complexity, the component size, the requested quantity as well as the application. While processing of prepreg materials and moulding compound have limitations, processing of dry semi-finished fabrics to complex textile forms (performs) with following impregnation (Liquid Composite Moulding – LCM) has a wider range of applications. LCM provides an opportunity to manufacture FRP components economical.

Challenges

Beside the good economic efficiency of the process, it still has enormous potential for reducing manufacturing costs. A closer look into the distribution of the manufacturing costs of FRP components shows saving potentials in the preforming process. The current technologies have low profitability concerning cycle times, material offcuts and quality. To increase the economic efficiency and reduce production costs, new technologies have to be developed and linked to new intelligent preforming process chains.

ITA-Preformcenter

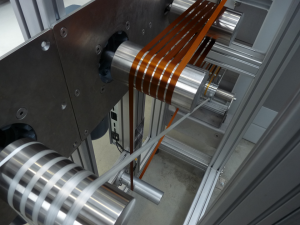

Based on the challenges above, the Institut für Textiltechnik (ITA) of the RWTH Aachen University offers a suitable industry-oriented research and development platform for the development of new individual technologies and preforming process chains for an economic manufacture of textile preforms: ITA-Preformcenter. For this purpose, technologies for 2D cutting and 3D cutting (ultrasonic cutting technology, laser technology), handling (vacuum gripper, needle gripper, ice gripper) and joining (sewing technology, binder application) of reinforcement fibres are available as well as new tooling concepts. Existing opportunities at ITA-Preformcenter enable the combination of technologies and new innovative performing process chains. Our in-house developed methods for economic efficiency analysis enable a theoretical evaluation as well as a comparison of process chains, which will finally be depicted and validated at ITA-Preformcenter.

Youtube-Channel: https://www.youtube.com/user/Preformcenter

_______________________________________________________________________________________________________

About the Institut für Textiltechnik (ITA) of RWTH Aachen University

The Institut für Textiltechnik (ITA) belongs to the elite university RWTH Aachen. Its area of core expertise is the development of textile machinery and components, high performance fiber materials, manufacturing technologies and comprehensive process chains and the development of innovative textile based products in the sectors of mobility, civil engineering and living, energy and health. The essential technology fields of its research are material and energy efficiency, functional integration and integrated production technologies. With the opening of the Centre for High Performance Materials in December 2012, ITA offers small and medium sized companies direct access to scientific research especially in the fields of high modulus fibres and composites. ITA provides research and development services and advanced training and creative workshops in coopera-tion with its partner company ITA Technologietransfer GmbH. Furthermore, ITA graduates students in various textile related courses. Please find further information at www.ita.rwth-aachen.de