This post is by Elham Saberi, Scientific Assistant in the Process And Data Science group at RWTH Aachen University. Contact her via email for further inquiries.

Salvador Dalí, The Persistence of Memory, 1931. From Wikipedia

Process Mining studies the flow of work in an automated business process, from an initial to the final point, in order to find bottlenecks and parts in which time and money can be saved or processes can run more systematically and efficiently.

Conformance analysis, which is an essential procedure within process mining, represents how much the behavior described by a process model is in line with the behavior that is captured in an event log; additionally, performance analysis how much time is consumed in different parts of the executions. In particular, this type of analyses is useful to identify bottlenecks that are situations where the process execution slows down or in the worst case it is blocked.

“Time is Gold” so let’s get rid of bottlenecks!

Performance analysis is useful to detect bottlenecks or parts of process that are repeated several times and that leads to a longer trace execution.

When we deal with “real data”, we face with some common questions such as: How long does it take to execute a particular transition? Where are the “time holes” in the process? What are the necessary actions to speed up the process?

One of the ways to speed up the process is to change our global viewpoint to a more local and specific view that enables us to consider one individual place (with its pre-sets and post-sets) and concentrate on its behavior.

Global vs Local view – “Small is Beautiful” so think globally act locally!

There are numerous analysis tools (beside human brain!) which are perfect in doing local analysis, while global analysis generally provides less detailed information. That means, we have to compromise global and local analysis in order to have a balanced view on both. Local analysis, anyhow, is faster, to-the-point, with power to provide detailed diagnoses.

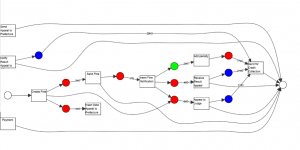

During a pilot research work at PADS RWTH a novel method was developed to align an event log and a Petri net containing visible unique transitions. This method provides a localized analysis by focusing on places in a process model. The method is faster in comparison to classic Conformance and Performance Analysis techniques like alignment-based and token-based replay; we called this new method IC-pairing alignment (IC stands for token Insertion and token Consumption).

In this localised analysis we deal with three scenarios: a place can be “fitting” (green places), “underfed” (blue places), or “overfed” (red places).

Colour-coded Petri net resulted from an IC-pairing alignment, which supports localized analysis.

This new type of alignment gives advantages to support process analysis more effectively, by detecting the lost time in process loops and the periods in the time interval in which the process has been most efficient (avoiding for example the re-opening of the whole process or the execution of additional activities). In addition, it is able to detect which constraints (places) in the process have problems, enabling the usage of repair techniques to improve the process model and making it more conform to the reality.