Fast, faster, the speed of light – a characteristic of modern data communication and the reason why a physicist found her way into the electrical engineering world.

Rebecca is a physicist and has been working as a cleanroom engineer at the Institute of Integrated Photonics at RWTH Aachen University since 2020. Here she gives an exclusive insight into her everyday working life.

Career guidance is often a challenge for school students. Rebecca, how did you find your way?

“Even in primary school I was very interested and enthusiastic about STEM subjects. Thanks to a dedicated and motivated physics teacher at secondary school, I decided to study physics instead of maths and physics as a teacher. I wanted to keep my options open for the future. I ‘fell in love’ with research during my bachelor’s thesis and have stayed with it ever since.”

Photonics is the technical mastery of light, which has many fascinating properties. What is photonic-electronic integration?

“Most people are familiar with electronic microchips. Integrated photonics is now concerned with implementing these functionalities on photonic microchips, where photonic signals are carried, manipulated and measured instead of electrical signals. The two microchips can also be combined or integrated to take advantage of the best features of both technologies.”

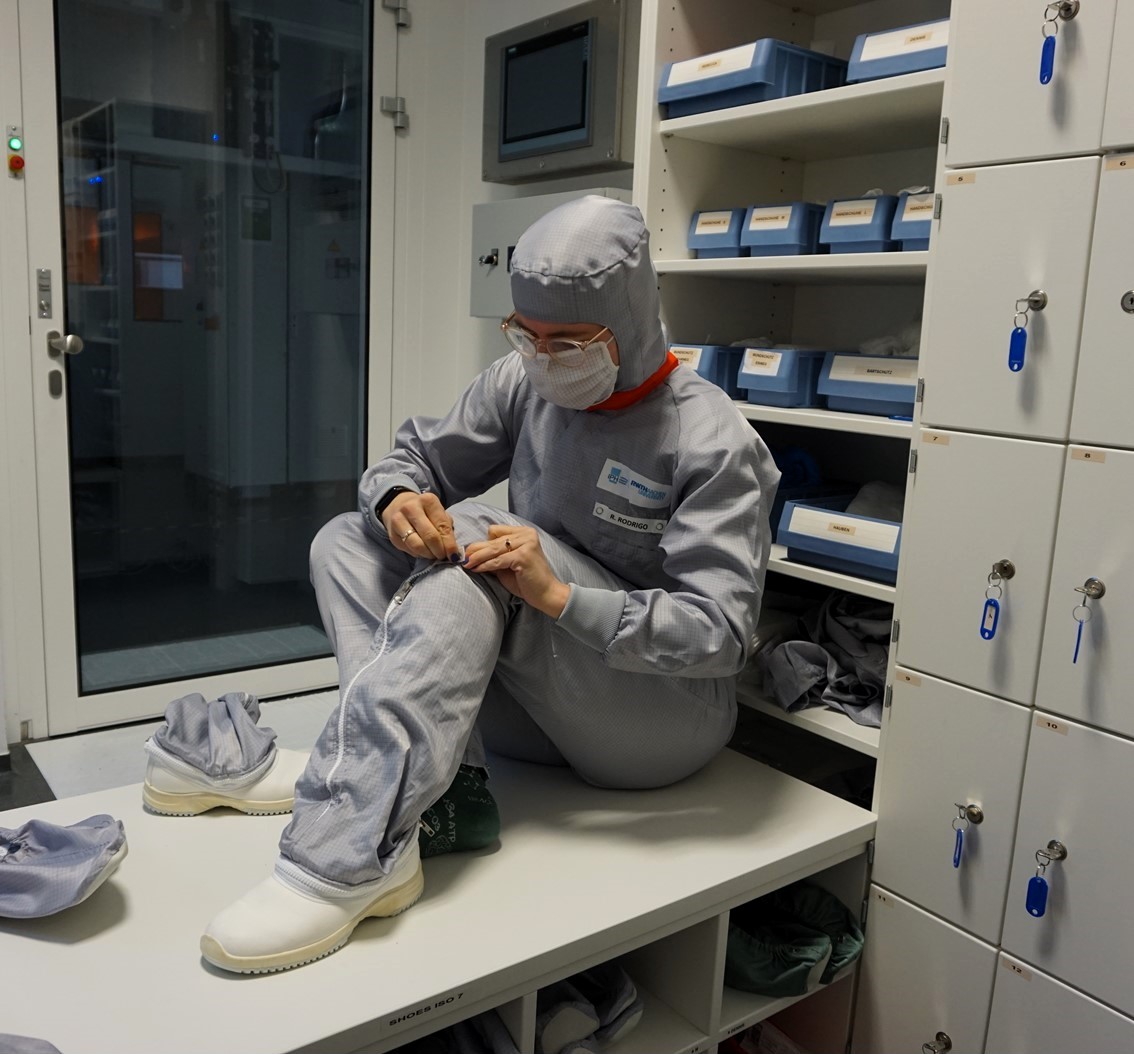

A personnel airlock leads into the cleanroom. Rebecca wears abrasion-resistant clothing to protect the ultra-sensitive microchips.

The cleanroom provides a controlled environment for specialised manufacturing processes such as the production of photonic integrated circuits on computer chips. What conditions are required in the cleanroom and why?

“The extremely low-particle environment is obviously very important, because even the smallest dust particle that gets on a microchip during the manufacturing process can affect its functionality. In our cleanroom, for example, we have only 100,000 particles larger than 0.1 micrometres per cubic metre, compared to 150 to 1000 times more in normal ambient air. The relative humidity and temperature in the cleanroom are also strictly monitored and kept constant, as the chip manufacturing processes are very sensitive.”

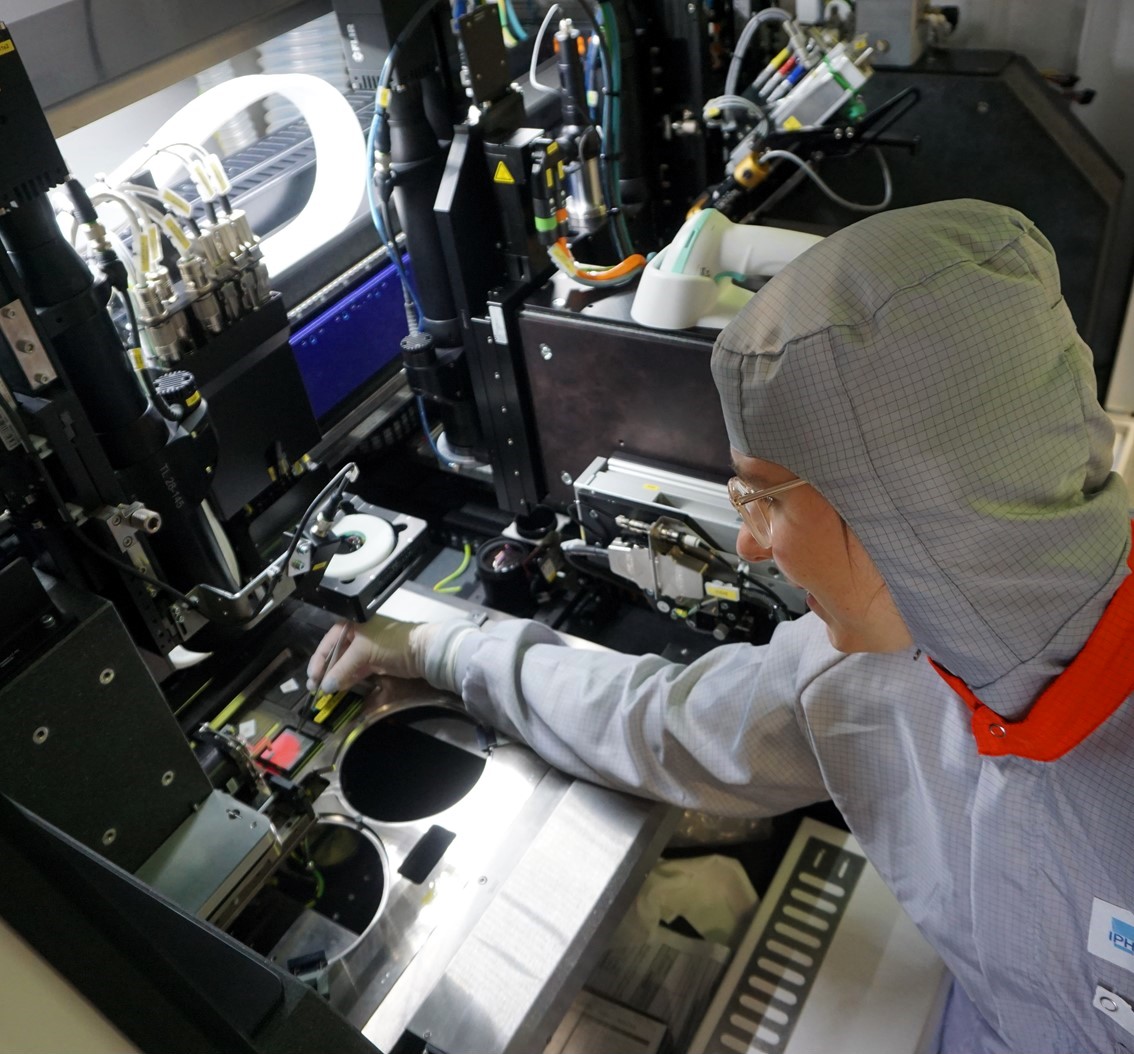

Rebecca works on the die-bonder using flip-chip technology: for chips to work properly, they need to be assembled and interconnected. The design and manufacture of these connections is known as packaging.

Photonic-electronic integration is a key technology for digitalisation. It meets the challenge of transporting and processing more and more data as we move towards a new information society. How exactly does this technology contribute to the solution?

“Most people are familiar with fibre optic technology from everyday life. Its advantages in data transmission lie primarily in its speed, but also in its energy efficiency compared to copper technology. We use the same principle, just miniaturised on a chip. It is no longer called fibre optics, but waveguides – but the basic principle is the same!

The advantage of photonics in data communications, whether over long distances as fibre-optic cables or miniaturised in chips for data centres, is therefore speed: we are unlikely to go faster than the speed of light in the foreseeable future. Parallelisation is also a clear advantage: different signals can be transmitted in parallel at different wavelengths or polarisations.”

What groundbreaking developments is the Institute of Integrated Photonics involved in? Which projects are you especially excited about?

“We have a lot of exciting projects and my role has the advantage that I am basically involved in all of them. There are certainly two projects that are particularly exciting in terms of these future technologies.

In the ML4Q cluster, we are involved in the development of a quantum computer. Many people are probably aware of the importance of this technology, for example in the field of quantum cryptography and supercomputing. Our specific task in this project is to realise a highly efficient photonic interface between spin qubits.

In the NeuroSys cluster, the IPH is working on a physical neural network based on photonic neurons. It is therefore a photonic AI. However, due to the size of such neural networks integrated on chips, it is not so much an AI like Chat GPT, but rather highly specialised and trained networks that score points in data centres for their enormous speed.”

Rebecca’s office is a space for dynamic workflows and creative ideas.

What is your typical working day like?

“On a day-to-day basis, I sometimes work very application-oriented directly in chip production on the systems and also train other employees in the application. At the same time, a large part of my work consists of designing new production processes, advising my colleagues as an expert in clean room technology, scientific research and coordinating a lot of maintenance work, for example. I also have management responsibility for my small cleanroom team, which consists of one permanent employee and several students. Supervision of final theses is also part of my job.”

What does work-life balance mean to you?

“Work-life balance is very important to me. For me personally, it is really about balance. Last autumn, I had the privilege of becoming a mother to a beautiful little girl who is, of course, my world. Together with my partner, we have decided to share caring and paid work 50:50. For me, this is the perfect solution and the best of both worlds: playing and exploring with my daughter is great fun and keeps me grounded, while my job helps me to get out of the baby bubble and focus on intellectual issues.”

Are you in the process of career exploration? Stay tuned and be inspired by further insights into the working life of academics at RWTH Aachen University. Visit our website and find out more about our degree programmes.

Leave a Reply