Kategorie: ‘Entwicklung’

April 29th, 2024 | by

Jansen, Christina

As part of the RobWeld project, new wrists and gripping mechanisms were developed for the PARAGRIP developed and built at IGMR.Through iterative design processes using rapid prototyping in 3D printing, we have perfected functionalities, ease of assembly and the manufacturability of components. The result? An elaborate design that combines steel and aluminum components.In the next step, the design can now be extensively tested before it is used on the robot.

You can find more information about the RobWeld project here.

Contact person:

Jan Wiartalla

Kategorie: Allgemein, Entwicklung, Entwicklung und Konstruktion, Greiferentwicklung, Prototypen, Prototypenbau

No Comments »

November 13th, 2020 | by

Ruland, Stefan Wolfgang

At IGMR, the haptic feedback system RePlaLink (Reconfigurable Planar Linkage) is being developed. With this system, hand-actuated mechanisms can be haptically simulated and interactively synthesized. Furthermore, users can interactively synthesize these mechanisms. This should allow mechanisms with optimal haptic properties to be developed.

People frequently interact with hand-actuated mechanisms in everyday life, e.g., in car doors, furniture doors, reconfigurable furniture, or fitness equipment. Their haptic properties largely determine the perceived quality of these mechanisms. The RePlaLink (Reconfigurable Planar Linkage) aims to support the design and development of these mechanisms by applying haptic feedback systems based on virtual prototypes. The haptic simulation and synthesis method allows users to directly feel mechanisms’ kinematic and kinetostatic properties while operating the system. In addition, users can interactively modify these properties and receive direct haptic feedback. In the first video, the design of the RePlaLink, consisting of a planar five-link with an additional serial link for the handle, is shown.

https://youtu.be/pemrysX4Cr8

The second video shows haptic simulation and synthesis using a kitchen cabinet door as an example.

https://youtu.be/0AqONOv1R5E

Project page:

https://www.igmr.rwth-aachen.de/index.php/de/gt/gt-replalink

Contact:

Mahshid Pour Ebrahimabadi M.Sc.

Kategorie: Entwicklung, Entwicklung und Konstruktion, Haptisches Feedbacksystem, IGMR, RePlaLink, Roboterprogrammierung, SPS, Virtuelle Inbetriebnahme, Virtuelle Prototypen

No Comments »

September 18th, 2020 | by

Ruland, Stefan Wolfgang

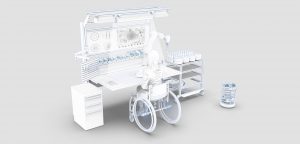

Person sits at a production workplace and is supported by a collaborative robot.

The Next Generation project aims to develop inclusive workplaces with the help of human-robot collaboration (HRC) in order to improve the quality of life.

People with severe and multiple disabilities usually work below their personal cognitive abilities. This causes great dissatisfaction.

For this reason, the project “Next Generation – developing inclusive work with flexible robot solutions” develops workplaces with the aid of human-robot collaboration (HRC).

The project is intended to enable people with disabilities to participate in working life. This can increase the quality of life as well as self-determination and positive personality development.

For tasks from industry, numerous companies from the Cologne area were asked to provide possible sample applications for the conception of the inclusive workplace.

In the process, two activities at Buschhoff Stanztechnik GmbH & Co. KG and at Cölner Hofbräu P. Josef Früh KG were selected. The conception and implementation can now begin. Further up-to-date information is available on the website of the Next Generation project.

Website Next Generation-Project.

Contacts:

Elodie Hüsing

Carlo Weidemann

Kategorie: Entwicklung, Entwicklung und Konstruktion, IGMR, Inklusive Arbeitsplätze, Mensch-Maschine-Kollaboration, Mensch-Roboter-Kollaboration, Next Generation

No Comments »