Next Generation project wins 3rd Digital Prize

Together with our project partners Caritas Wertarbeit Köln e.V. and the Fachhochschule des Mittelstands (University of Applied Sciences for Small and Medium Enterprises), we accepted the third place in the Digital Prize and the prize money of 2,000 euros for the Next Generation project at the Futurium in Berlin on Tuesday, 3 May.

The Digital Prize is being awarded for the second time since 2019. According to the theme ‘Digital Inclusive’, the CBP aims to promote the use of digital technologies for people with disabilities and mental illnesses in the fields of disability assistance, psychiatry, politics, research, and business. At the end of the project, we are delighted to have received this award and would like to thank all those involved in and supporting the project. Next Generation is funded by the Stiftung Wohlfahrtspflege NRW, the Landschaftsverband Rheinland and the Caritasverband der Stadt Köln e.V.

Der an dieser Stelle eingebundene Inhalt führt Sie auf Seiten, die von der von Google betriebenen Seite YouTube - YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA - zur Verfügung gestellt werden. Mit dem Aufruf des Inhalts kann YouTube Ihre IP-Adresse und die Sprache des Systems, sowie verschiedene browserspezifische Angaben ermitteln. Wenn Sie in Ihrem YouTube-Account eingeloggt sind, ermöglichen Sie YouTube, Ihr Surfverhalten direkt Ihrem persönlichen Profil zuzuordnen. Dies können Sie verhindern, indem Sie sich aus Ihrem YouTube-Account ausloggen. YouTube verwendet Cookies und Tracking-Tools. Die Datenverarbeitungsvorgänge sowie die Zwecke der Verarbeitung können direkt bei YouTube erfragt und eingesehen werden.

Contacts:

Mathias Hüsing

Carlo Weidemann

Elodie Hüsing

Workshop on environmental perception in Sharework

During the training workshop titled ‘Manufacturing Environment Perception for Effective Human-Robot Collaboration,’ we presented topics related to workspace monitoring and object recognition using simple learning methods. The presentation included a brief theoretical introduction to machine learning with random forests, an overview of the IGMR work packages in Sharework, and some tips for using these methods in your own projects. The presentation covered not only our work packages but also the contributions of our partners, particularly in the areas of ontology and motion primitives.

Der an dieser Stelle eingebundene Inhalt führt Sie auf Seiten, die von der von Google betriebenen Seite YouTube - YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA - zur Verfügung gestellt werden. Mit dem Aufruf des Inhalts kann YouTube Ihre IP-Adresse und die Sprache des Systems, sowie verschiedene browserspezifische Angaben ermitteln. Wenn Sie in Ihrem YouTube-Account eingeloggt sind, ermöglichen Sie YouTube, Ihr Surfverhalten direkt Ihrem persönlichen Profil zuzuordnen. Dies können Sie verhindern, indem Sie sich aus Ihrem YouTube-Account ausloggen. YouTube verwendet Cookies und Tracking-Tools. Die Datenverarbeitungsvorgänge sowie die Zwecke der Verarbeitung können direkt bei YouTube erfragt und eingesehen werden.

Contact:

Daniel Gossen

Transformation of workplaces by human-robot collaboration (HRC) at Ford

Since April 2021, employees with disabilities have been working successfully with a collaborative robot at the production line of Ford engine plant in cologne. The robot takes over the unergonomic pressing of the VCT solenoids into the engine cover and the employee installs the screws. During this process, humans and robots work simultaneously in the same workspace. The key findings and results of the project are summarized in the strategy paper.

Further information on the project can be found here.

Contact:

Development of new wrists for the Paragrip

In a joint research project of the IGMR together with the ISF of the RWTH Aachen University, the Multidirectional Additive Manufacturing (MDAM) of metallic components is being researched. In order to optimize the multi-armed. Paragrip robot for this application, student Raphael Hoffmann has developed an innovative concept of a new robotic wrist in his bachelor thesis. The concept enables the welding current to be conducted directly through the wristsm without the need for an additional ground cable attached to the print bed. Moreover, the wrists enable form fitting gripping of the print bed with self-centering to minimize positioning inaccuracies.

You can find the video on our YouTube channel: https://youtu.be/VdT1rjYG4D0

Contact:

Jan Wiartalla

MobiLamas

MobiLamas is a concept for free-float charging in the city of the future. In our vision, individual transport will shift from cars to public transport, complemented by so-called last-mile vehicles (e.g., electric bikes or scooters). In such environments, ecological and economical solutions are needed to enable safe and smart charging for a variety of devices. MobiLamas are intelligent mobile robots that interact with last-mile vehicles and charging stations, and safely navigate urban spaces in the presence of pedestrians.

Contact:

IGOR – our in-house robot

Markus Schmitz

How construction site robots work on a wall

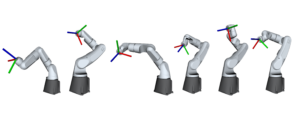

The in-house developed robot has 7 degrees of freedom, which are realized exclusively via revolute joints. Due to the redundancy, the robot can also develop its full performance in narrow situations such as corridors or niches. The video on the left shows a vertical trajectory in which the robot works on a wall from the floor to a height of 2.50m. The video on the right shows the horizontal trajectory of a wall immediately in front of the robot.

More information about this project can be found on the IGMR Website.

Contact person:

Lösungen der Praktischen Übungen in Robotic Systems

Auch in diesem Jahr haben uns wieder kreative Lösungen für Problemstellungen aus dem Modul Robotic Systems erreicht. Die Studierenden konnten erste Erfahrungen bei der Programmierung eines Fanuc Roboters in Roboguide sammeln. Eine Umfangreiche Programmieraufgabe galt es weiterhin an der Fanuc Education Cell zu lösen. Auf Grund der Einschränkungen der Präsenzveranstaltungen mussten alle Lösungen virtuell in Roboguide gelöst werden. Im nächsten Winter wird dann wieder am realen Roboter erprobt.

Ansprechpartner: