Schlagwort: ‘ROS’

IGMR Seminar 08.02.2021 14:30 Uhr: Dr. Stefan Kurtenbach, Trapo AG

Wir begrüßen Dr. Stefan Kurtenbach von der Trapo AG zum IGMR Seminar. Auch diese Veranstaltung wird weiterhin virtuell durchgeführt:

Der Vortrag von Dr. Kurtenbach wird einen Eindruck der aktuellen Entwicklungen und Produkte von der Trapo AG geben.

Trapo Research and Development: Mobile Robotics

Montag, 08. Februar 2021 14:30 Uhr

Zoom Meeting Informationen:

https://rwth.zoom.us/j/98454895570?pwd=NkpiSWkyaTJtdWlralJrSUtnMDdDZz09

Meeting-ID: 984 5489 5570

Kenncode: 186393

Die Datenschutzhinweise zur Nutzung von Zoom und eine Handreichung für Teilnehmer (Studierende) können von den Seiten des CLS der RWTH Aachen University heruntergeladen werden.

Die Veranstaltungen im Wintersemester 2020/2021 werden in Zusammenarbeit mit dem VDI-GPP-Arbeitskreis des Bezirksvereins Aachen durchgeführt.

Weitere Informationen zum Thema können den folgenden Blogeinträgen entnommen werden:

Industrieprojekt Trapo Loading System

Ansprechpartner:

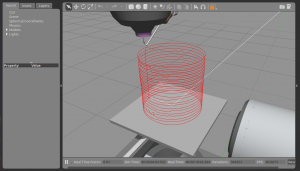

Manipulator-specific path planning for multidirectional additive manufacturing

In a joint research project between the IGMR and the ISF of RWTH Aachen University, research is being conducted on the Multidirectional Additive Manufacturing of metallic components.

With the aid of Multidirectional Additive Manufacturing (MDAM), it is possible to build complex components layer by layer and without the need for support structures. By moving the base plate by means of an industrial robot while the welding gun remains fixed, the component to be printed can always be oriented in such a way that support structures can be avoided. The major challenge lies in the consideration of specialized welding processes with external wire feeding and the use of sensors for process monitoring. This results in a dependency of the orientation of the welding gun compared to the currently printed path.

As part of his master’s thesis, Jan Wiartalla developed a path planning algorithm that calculates an executable and, if possible, continuous path within specified, flat part slices that completely fills the cross-sectional area. This is done robot-specific, so that the algorithm always takes the robot currently in use as well as its limitations into account. A standardized interface allows for the robot model to be easily exchanged and the algorithm can thus quickly be adapted to different test environments. The video illustrates the algorithm’s procedure in a simplified way.

Der an dieser Stelle eingebundene Inhalt führt Sie auf Seiten, die von der von Google betriebenen Seite YouTube - YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA - zur Verfügung gestellt werden. Mit dem Aufruf des Inhalts kann YouTube Ihre IP-Adresse und die Sprache des Systems, sowie verschiedene browserspezifische Angaben ermitteln. Wenn Sie in Ihrem YouTube-Account eingeloggt sind, ermöglichen Sie YouTube, Ihr Surfverhalten direkt Ihrem persönlichen Profil zuzuordnen. Dies können Sie verhindern, indem Sie sich aus Ihrem YouTube-Account ausloggen. YouTube verwendet Cookies und Tracking-Tools. Die Datenverarbeitungsvorgänge sowie die Zwecke der Verarbeitung können direkt bei YouTube erfragt und eingesehen werden.

Contacts:

IGMR Seminar: Dr. Michael Cashmore – Plan-Based Robot Control in Real-Time

Mit dem Vortrag von Dr. Miachel Cashmore von der University of Strathclyde startet die virtuelle IGMR Vortragsreihe im Wintersemester 20/21. Wir freuen uns auf einen Einblick in ROSPlan und Plan-Based Robot Control in Real-Time.

Mittwoch, 2. Dezember 2020 16:30 Uhr in Zoom Zoom Meeting Informationen: https://rwth.zoom.us/j/98454895570?pwd=NkpiSWkyaTJtdWlralJrSUtnMDdDZz09 Meeting-ID: 984 5489 5570, Kenncode: 186393

Die Datenschutzhinweise zur Nutzung von Zoom und eine Handreichung für Teilnehmer (Studierende) können von den Seiten des CLS der RWTH Aachen University heruntergeladen werden.

The topic of the seminar will focus on the numerous temporal and numeric challenges that arise in plan execution. If a plan is produced with some flexibility, how it can be executed? In this context the properties of temporal controllability, robustness envelopes, replanning in-situ, and planning concurrently to execution, deliberation in a system of distributed components, in which your actions can affect other parts of a larger system will be discussed.

Die Veranstaltungen im Wintersemester 2020/2021 werden in Zusammenarbeit mit dem VDI-GPP-Arbeitskreis des Bezirksvereins Aachen durchgeführt.

Robot Companion: A mobile helper in case of need

Robot Companion is a framework to implement robot tracking systems in a simple and cost-saving way. For this purpose, IGMR develops methods for tracking with different sensors (laser, radar, camera), agile path planning and actuation.

The current objective of Robot Companion is to provide a robot for emergency rescue. In doing so, the robot will autonomously follow first responders and enable the transport of materials and equipment, as well as the removal of debris and casualties. A first path to this vision was implemented with the basic module. The basic module has methods for tracking with a camera and laser, and enables autonomous tracking of an operator.

The video shows the tracks of the vertical and horizontal trackers, as well as the state of detection (top right). In a tracking test, 100% accuracy was achieved at low speeds.

Der an dieser Stelle eingebundene Inhalt führt Sie auf Seiten, die von der von Google betriebenen Seite YouTube - YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA - zur Verfügung gestellt werden. Mit dem Aufruf des Inhalts kann YouTube Ihre IP-Adresse und die Sprache des Systems, sowie verschiedene browserspezifische Angaben ermitteln. Wenn Sie in Ihrem YouTube-Account eingeloggt sind, ermöglichen Sie YouTube, Ihr Surfverhalten direkt Ihrem persönlichen Profil zuzuordnen. Dies können Sie verhindern, indem Sie sich aus Ihrem YouTube-Account ausloggen. YouTube verwendet Cookies und Tracking-Tools. Die Datenverarbeitungsvorgänge sowie die Zwecke der Verarbeitung können direkt bei YouTube erfragt und eingesehen werden.

Project website:

https://www.igmr.rwth-aachen.de/index.php/de/rob/rob-comp

Contact:

Multidirectional additive manufacturing in arc welding process

In collaboration with the ISF, RWTH Aachen, we at IGMR are researching Multidirectional Additive Manufacturing. In this application for the production of metal components.

Multidirectional Additive Manufacturing enables the production of complex components without support structures, both in the classic FDM process with plastic and with layer-by-layer buildup in the arc welding process. At IGMR, the entire process chain of additive manufacturing is being extended to meet the special challenges of this process from a robotic perspective. This includes the slicing of a virtual component into layers, the subsequent planning of a collision-free structure, the generation of executable robot paths for filling the layers as well as the necessary trajectory planning.

The content embedded at this point takes you to pages provided by the YouTube site operated by Google – YouTube, LLC, 901 Cherry Ave, San Bruno, CA 94066, USA. By calling up the content, YouTube can determine your IP address and the language of the system, as well as various browser-specific details. If you are logged into your YouTube account, you enable YouTube to assign your surfing behavior directly to your personal profile. You can prevent this by logging out of your YouTube account. YouTube uses cookies and tracking tools. The data processing operations as well as the purposes of the processing can be requested and viewed directly at YouTube.

Contact person:

Markus Schmitz

Carlo Weidemann

Der an dieser Stelle eingebundene Inhalt führt Sie auf Seiten, die von der von Google betriebenen Seite YouTube - YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA - zur Verfügung gestellt werden. Mit dem Aufruf des Inhalts kann YouTube Ihre IP-Adresse und die Sprache des Systems, sowie verschiedene browserspezifische Angaben ermitteln. Wenn Sie in Ihrem YouTube-Account eingeloggt sind, ermöglichen Sie YouTube, Ihr Surfverhalten direkt Ihrem persönlichen Profil zuzuordnen. Dies können Sie verhindern, indem Sie sich aus Ihrem YouTube-Account ausloggen. YouTube verwendet Cookies und Tracking-Tools. Die Datenverarbeitungsvorgänge sowie die Zwecke der Verarbeitung können direkt bei YouTube erfragt und eingesehen werden.

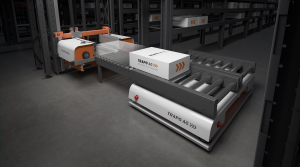

Industrial project Trapo Loading System

Image source: Pressemitteilung Trapo AG

IGMR – RWTH Aachen supports Trapo AG in the development and integration of trajectory planning and trajectory execution algorithms, environment perception and communication with the PLC for the new Trapo Loading System robot.

Link to the press release of Trapo AG:

https://www.trapo.de/de/presse/artikel/das-tls-3600-entzerrt-die-gefahrenzone-im-be-und-entladebereich/

Contact person:

Stefan Bezrucav

Markus Schmitz

SLAM validation using iGPS

For the validation of localization and mapping algorithms (SLAM) for mobile robots, we use at IGMR the indoor Global Positioning System from Nikon.

SLAM is a classical problem in mobile robotics and still a current and challenging research topic. The current developments are focused in improving SLAM algorithms with respect to a high accuracy, generality, and robustness. For this reason, we validate our SLAM algorithms for mobile robotics with the Nikon iGPS which is used to generate a ground truth with a frequency of 40 Hz and an accuracy of 0.2 mm. In this way, critical inaccuracies and loop closure methods can be much better quantified and analyzed.

Project page:

Bots2Rec

Contact person:

Simon Schläger

WAAM simulation with ROS in Gazebo

Vincent Brünjes designed a Gazebo plug-in in his master‘s thesis to simulate multidirectional wire+arc additive manufacturing processes.

Contacts:

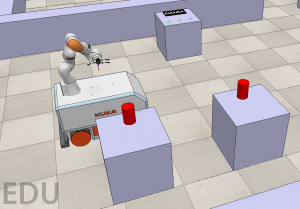

Execution of the planned actions in CoppeliaSim

Implementation of ROS Action Interfaces to connect the AI task planning framework ROSPlan with the simulation software CoppeliaSim

Contact person: