February 26th, 2026 | by

Jansen, Christina

Der an dieser Stelle eingebundene Inhalt führt Sie auf Seiten, die von der von Google betriebenen Seite YouTube - YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA - zur Verfügung gestellt werden. Mit dem Aufruf des Inhalts kann YouTube Ihre IP-Adresse und die Sprache des Systems, sowie verschiedene browserspezifische Angaben ermitteln. Wenn Sie in Ihrem YouTube-Account eingeloggt sind, ermöglichen Sie YouTube, Ihr Surfverhalten direkt Ihrem persönlichen Profil zuzuordnen. Dies können Sie verhindern, indem Sie sich aus Ihrem YouTube-Account ausloggen. YouTube verwendet Cookies und Tracking-Tools. Die Datenverarbeitungsvorgänge sowie die Zwecke der Verarbeitung können direkt bei YouTube erfragt und eingesehen werden.

As part of the FunkDAF research project, the IGMR is working with the MSE and VCI at RWTH Aachen University to explore the limits of additive manufacturing. Our focus is on multidirectional manufacturing: instead of breaking down components into planar layers as in conventional 3D printing, we generate print paths based on stress data to create load-path-compatible and thus more stable structures.

The kinematics: We use a 6-axis industrial robot in a “robot-guided” configuration. The robot guides the print bed and component under a stationary extruder. This use of all six degrees of freedom enables the printing of complex, non-planar geometries and allows component sections to be manufactured in variable orientations to gravity.

The challenge: Trajectory planning for such systems is highly complex. Unlike static print beds, we are moving a dynamically growing workpiece in space. During the process, the component itself becomes a potential collision object with respect to the nozzle and the environment. To make matters more difficult, the extrusion process requires a minimum working distance from the stationary nozzle. Path planning must therefore not only take extrusion into account, but also precisely calculate how the component volume changes.

The travel paths (empty runs) between individual printing segments are particularly critical. Here, the robot often has to completely reorient the component in order to reach the next section without collision. Our current experiments (see images) demonstrate this impressively:

Helix on cylinder: Requires continuous, coordinated rotation to deposit material on a curved surface.

Orthogonal cuboids: Demonstrate the ability to print overhangs without support structures through a 90° reorientation.

Contact person: Mark Witte

Further information about the project can be found here.

Kategorie: Aufgabenplanung, Bahnplanung, C++, MDAM, Planung, Python, Roboterprogrammierung, ROS, Trajektorie

Keine Kommentare »

December 2nd, 2025 | by

Jansen, Christina

We had the great pleasure of welcoming Frank Schwabe from FANUC Europe – Technical Center RO for an exciting guest lecture in our Robotic Systems course. Mr. Schwabe provided our students with an engaging introduction to industrial robotics, presenting FANUC’s technologies, product portfolio, and real-world applications in automation. The students were highly motivated, asked many insightful questions, and gained valuable perspectives on how modern robotics shapes today’s manufacturing environments. A big thank you to Mr. Schwabe and FANUC for their support and for inspiring the next generation of engineers!

Kategorie: Fanuc, Fanuc Education Cell, Fanuc Olympiade, Industrial Robotics, Industrie, Roboter, Robotic Systems

Keine Kommentare »

September 5th, 2025 | by

Jansen, Christina

Der an dieser Stelle eingebundene Inhalt führt Sie auf Seiten, die von der von Google betriebenen Seite YouTube - YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA - zur Verfügung gestellt werden. Mit dem Aufruf des Inhalts kann YouTube Ihre IP-Adresse und die Sprache des Systems, sowie verschiedene browserspezifische Angaben ermitteln. Wenn Sie in Ihrem YouTube-Account eingeloggt sind, ermöglichen Sie YouTube, Ihr Surfverhalten direkt Ihrem persönlichen Profil zuzuordnen. Dies können Sie verhindern, indem Sie sich aus Ihrem YouTube-Account ausloggen. YouTube verwendet Cookies und Tracking-Tools. Die Datenverarbeitungsvorgänge sowie die Zwecke der Verarbeitung können direkt bei YouTube erfragt und eingesehen werden.

In pick-and-place tasks, which are often implemented with delta robots in industrial practice, short cycle times are desired. These lead to high accelerations of the robot and thus to high inertial forces, which cause the frame to vibrate. The frame vibrations reduce the performance and positioning accuracy of the robot and lead to material fatigue. To reduce frame vibrations, we have developed an optimal control approach that calculates vibration-reducing trajectories. To reduce vibrations, the free frame vibration is suppressed at the end of the trajectory. The chosen approach optimizes the trajectory holistically, i.e., both the geometric path and the motion law along the path are optimized. The optimization uses a multibody simulation model that was constructed with the aid of experimental system identification. Application- and robot-specific boundary conditions can be taken into account in the calculation of vibration-reducing trajectories.

contact:

Nils Brückmann

Christian Mirz

Preprint of the corresponding paper can be found here.

Further information on the Delta robot can be found here.

Kategorie: Parameteridentifikation, Simulationen, Trajektorie

Keine Kommentare »

June 5th, 2025 | by

Jansen, Christina

How can objects be gripped safely and gently at the same time – without any traditional joints?

With this 3D-printed prototype, we demonstrate how topological optimization and compliant mechanisms together open up new paths in robotic gripping.

The design is based on flexible structures that can be strongly deformed through targeted geometry adjustment – ideal for adapting to spherical objects, for example.

Objective:

– Maximization of the contact surfaces

– Even distribution of forces

– Reduction of damage to the object

Thanks to additive manufacturing and computer-aided design, complex, high-performance structures could be implemented that would be almost impossible to realize using conventional methods.

Contact person:

Estefania Hermoza Llanos

Kategorie: Additive Fertigung, Additive Manufacturing, Greiferentwicklung

Keine Kommentare »

April 14th, 2025 | by

Jansen, Christina

In March, we were able to take part in this year’s annual meeting at the Rhein-Mosel-Werkstätten in Koblenz as an exhibitor and network member of daaap.

A special highlight: The event was opened by Ms Schall, Minister for Labour, Social Affairs, Transformation and Digitization in Rhineland-Palatinate, among others. She took the time to get to know the IIDEA project and was even able to try out our model workplace for herself.

We are delighted with the interest shown in our project by the participating workshops. The direct exchange, valuable discussions and new contacts show that The vision of inclusive digitalization is shared and carried forward.

Contact person:

Mathias Hüsing

Kategorie: Allgemein, Cobot, IGMR, Kollaboration, kollaborierenden Roboter, Mensch-Maschine-Kollaboration, Mensch-Roboter-Kollaboration, Roboter, Robotik, Werkstatt

Keine Kommentare »

April 14th, 2025 | by

Jansen, Christina

Congratulations to Esteban and Gregory – they took 3rd place at this year’s championship at FANUC in Neuhausen and thus won bronze!

The task: a challenging battery assembly that had to be completed in just three days. The standard was particularly high this year and for the first time eight teams took part.

We are very proud of our two talents! Many thanks to Sophie Charlotte for making this participation possible!

Contact person:

Sophie Charlotte Keunecke

Kategorie: Fanuc, Fanuc Education Cell, Fanuc Olympiade, Industrial Robotics, Industrie, industrielle Robotik, Roboter, Robotik

Keine Kommentare »

March 5th, 2025 | by

Jansen, Christina

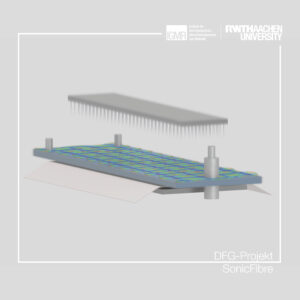

At the IGMR, we are working on the next generation of additive manufacturing as part of the DFG-funded FunkDAF research project together with the MSE and VCI institutes: layerless, multidimensional material deposition.

🔹 What does that mean?

Multiaxial additive manufacturing with a robot-guided print bed allows us to deposit material along specific stress paths. This leads to improved material utilization and reduces the disadvantages of layer-by-layer construction.

🔹 Our challenges:

– Precise robot guidance along the print paths

– Synchronization of extruder and robot movement

– Constant printing speed for maximum quality

The print paths are generated on the VCI from FEM stress data – resulting in mechanically optimized structures. 💡

Contact person:

Mark Witte – witte@igmr.rwth-aachen.de

Kategorie: Roboterprogrammierung, ROS, Trajektorie

Keine Kommentare »

March 4th, 2025 | by

Jansen, Christina

We kicked-off our new project “AuBa@C – Automation of Battery Disassembly using Advanced Hardware and Software for Battery Recycling” together with cylib. Here at IGMR, we conduct research into automated disassembly using robots. In the project together with cylib, we can transfer our expertise from projects such as Bots2ReC, SHEREC or di.monta to the disassembly of EV batteries.

We are excited to collaborate with cylib (Dr. Stefan-Octavian Bezrucav (Head of Pre-Processing and Robotics Expert) and Sara Ognjanovic (Project Manager for Automation in Battery Discharge and Disassembly).)

This project is supported by the “KUER.NRW | Grüne Gründungen Nordrhein-Westfalen” funding initiative, under the framework of the European Regional Development Fund (EFRE/JTF NRW 2021-2027), coordinated by the Ministry for the Environment, Nature Conservation, and Transport of North Rhine-Westphalia and the Projektträger Jülich (PtJ).

contact:

Stefan Groß