Schlagwort: ‘Mensch-Roboter-Kollaboration’

IGMR Seminar 11.02.2021 13:00 Uhr: Wameq Kazemi, Freise Automation GmbH

Bildquelle: Freise Automation GmbH

Wir begrüßen Herrn Wameq Kazemi von Freise Automation GmbH zum IGMR Seminar.

Auch diese Veranstaltung wird weiterhin virtuell durchgeführt:

Im Vortrag wird Herr Kazemi die kollaborative Roboterserie HRC von Hanwha vorstellen und außerdem einen Einblick in die Programmierung der HRC Cobots geben.

Agenda:

o Vorstellung Freise Automation

o Vorstellung HRC Series

o Programmieren des HRC

Der an dieser Stelle eingebundene Inhalt führt Sie auf Seiten, die von der von Google betriebenen Seite YouTube - YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA - zur Verfügung gestellt werden. Mit dem Aufruf des Inhalts kann YouTube Ihre IP-Adresse und die Sprache des Systems, sowie verschiedene browserspezifische Angaben ermitteln. Wenn Sie in Ihrem YouTube-Account eingeloggt sind, ermöglichen Sie YouTube, Ihr Surfverhalten direkt Ihrem persönlichen Profil zuzuordnen. Dies können Sie verhindern, indem Sie sich aus Ihrem YouTube-Account ausloggen. YouTube verwendet Cookies und Tracking-Tools. Die Datenverarbeitungsvorgänge sowie die Zwecke der Verarbeitung können direkt bei YouTube erfragt und eingesehen werden.

Zugangsdaten zum Online Meeting:

RWTH – Fresie Automation / Kollaborative Robotik

Do., 11. Feb. 2021 13:00 – 14:00 (CET)

Nehmen Sie an meinem Meeting per Computer, Tablet oder Smartphone teil.

https://global.gotomeeting.com/join/111521101

Sie können sich auch über ein Telefon einwählen.

(Bei Geräten, die diese Funktion unterstützen, ist die sofortige Teilnahme über eine der unten aufgeführten Direktwahlnummern möglich.)

Deutschland: +49 721 6059 6510

– Direktwahl: tel:+4972160596510,,111521101#

Zugangscode: 111-521-101

Sie kennen GoToMeeting noch nicht? Installieren Sie jetzt die App, damit Sie für Ihr erstes Meeting bereit sind: https://global.gotomeeting.com/install/111521101

Die Veranstaltungen im Wintersemester 2020/2021 werden in Zusammenarbeit mit dem VDI-GPP-Arbeitskreis des Bezirksvereins Aachen durchgeführt.

Ansprechpartner:

TCP and null space impedance for bypassing objects with the KUKA iiwa

In the video two different types of impedance control of the KUKA iiwa are shown: TCP and null space impedance. Furthermore, the bypassing of objects using impedance control has been implemented.

https://youtu.be/VHrV-nh5oTU

First, the two different types of impedance control are demonstrated. Different stiffnesses can be programmed around the individual TCP axes. Two different stiffnesses within a plane are shown in the video. On the other hand, there is null space impedance. In this case, the robot maintains the pose of the TCP and the elbow can be pushed away. As shown in the video, this can be used to bypass an object while maintaining the programmed TCP path.

Project page: NextGeneration

Contacts:

Igus Delta Demonstrator

Sebastian Lüke developed a demonstrator including control, trajectory planning and user interface for the igus Delta modular system as part of his master’s thesis.

Contacts:

Funding project for collaborative robot

![]()

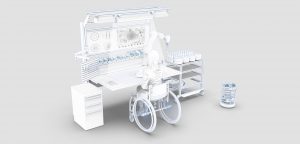

- The Rheinisch Westfälische Technische Hochschule (RWTH) Aachen, together with the Cologne-based car manufacturer Ford and the Landschaftsverband Rheinland (LVR), is conducting research on a workplace with a new version of a collaborative robot.

- LVR supports the model project with 372,000 euros from compensatory levy funds

- The new workstation meets the requirement for severely disabled employees

Aachen, June 24th, 2020 – Together with the Cologne-based car manufacturer Ford and the Landschaftsverband Rheinland (LVR), the Rheinisch Westfälische Technische Hochschule Aachen (RWTH) is working on a new application for a collaborative robot. The LVR is funding this model project entitled “Human-Robot Collaboration – Redesigning a Workplace in the Automotive Industry for Severely Disabled Employees” with 372,000 euros through its Inclusion Office from the funds of the compensatory levy. The aim is to integrate the robot into production so that a severely disabled person shares a workplace with the robot. The unique project feature is the robot, which is configured to work interactively “hand in hand” with the person and is not separated by a protective device.

The project officially started on June 1st, 2020. The task of the automotive manufacturer is to design the workplace and define the configuration so that it complies with the requirements of cycle-based manufacturing, occupational safety requirements, and barrier-free workplace design.

The project duration is 19 months (June 1st, 2020 to December 31st, 2021). The aim is to use this example implementation to gain insights into the employment of human-machine collaborations to safeguard the employment of severely disabled people and to advise small and medium-sized companies in this regard.

The Institute of Transmission Technology, Machine Dynamics and Robotics (IGMR) at RWTH Aachen University is involved in the project and, with its expertise in robotics and collaboration, ensures scientific support and further transfers.

The other partners of the RWTH:

Landschaftsverband Rheinland (LVR)

The LVR Inclusion Office is responsible for the participation of severely disabled people in the general labor market in the Rhineland. It offers various support services for employers and severely disabled people and works with different partners. The offers include, for example, financial support for the establishment of jobs and training positions, for the disability-friendly furnishing of workplaces, or in the case of extraordinary burdens during employment. For the LVR Inclusion Office, the expected and to-be-published knowledge gained from the new model project promises significant benefits for expanding employment opportunities for people with disabilities and using new technical developments to promote inclusion.

Ford-Werke GmbH is a German automotive manufacturer and mobility provider headquartered in Cologne. The company employs more than 22,000 people at its sites in Cologne, Saarlouis, and Aachen. Since its founding in 1925, Ford-Werke has produced more than 47 million vehicles.

Contact:

Prof. Dr.-Ing. Mathias Hüsing

stv. Institutsdirektor

Tel.: 0241 – 80 95554

E-Mail: huesing(at)igmr.rwth-aachen.de