Kategorie: ‘IGMR’

Robot Companion: A mobile helper in case of need

Robot Companion is a framework to implement robot tracking systems in a simple and cost-saving way. For this purpose, IGMR develops methods for tracking with different sensors (laser, radar, camera), agile path planning and actuation.

The current objective of Robot Companion is to provide a robot for emergency rescue. In doing so, the robot will autonomously follow first responders and enable the transport of materials and equipment, as well as the removal of debris and casualties. A first path to this vision was implemented with the basic module. The basic module has methods for tracking with a camera and laser, and enables autonomous tracking of an operator.

The video shows the tracks of the vertical and horizontal trackers, as well as the state of detection (top right). In a tracking test, 100% accuracy was achieved at low speeds.

https://youtu.be/imU8j2zlQrQ

Project website:

https://www.igmr.rwth-aachen.de/index.php/de/rob/rob-comp

Contact:

Cooperative mobile packaging in production lines in the “Internet of Production”

Applications of mobile manipulation in production lines of the “Factory of Future”.

Internet of Production (IoP) has the vision to enable cross-domain collaboration in production lines on a new level. Mobilization of robotic agents and resources are the essences of the production lines of the Factory of Future. To enable robotic agents to react to the changes in production lines, we at IGMR are developing online motion planning and control strategies for mobile manipulators in dynamic situations.

Der an dieser Stelle eingebundene Inhalt führt Sie auf Seiten, die von der von Google betriebenen Seite YouTube - YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA - zur Verfügung gestellt werden. Mit dem Aufruf des Inhalts kann YouTube Ihre IP-Adresse und die Sprache des Systems, sowie verschiedene browserspezifische Angaben ermitteln. Wenn Sie in Ihrem YouTube-Account eingeloggt sind, ermöglichen Sie YouTube, Ihr Surfverhalten direkt Ihrem persönlichen Profil zuzuordnen. Dies können Sie verhindern, indem Sie sich aus Ihrem YouTube-Account ausloggen. YouTube verwendet Cookies und Tracking-Tools. Die Datenverarbeitungsvorgänge sowie die Zwecke der Verarbeitung können direkt bei YouTube erfragt und eingesehen werden.

Further information on the Internet of Production:

https://www.igmr.rwth-aachen.de/index.php/de/rob/rob-iop

https://www.iop.rwth-aachen.de

Contact person:

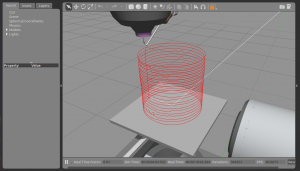

Multidirectional additive manufacturing in arc welding process

In collaboration with the ISF, RWTH Aachen, we at IGMR are researching Multidirectional Additive Manufacturing. In this application for the production of metal components.

Multidirectional Additive Manufacturing enables the production of complex components without support structures, both in the classic FDM process with plastic and with layer-by-layer buildup in the arc welding process. At IGMR, the entire process chain of additive manufacturing is being extended to meet the special challenges of this process from a robotic perspective. This includes the slicing of a virtual component into layers, the subsequent planning of a collision-free structure, the generation of executable robot paths for filling the layers as well as the necessary trajectory planning.

The content embedded at this point takes you to pages provided by the YouTube site operated by Google – YouTube, LLC, 901 Cherry Ave, San Bruno, CA 94066, USA. By calling up the content, YouTube can determine your IP address and the language of the system, as well as various browser-specific details. If you are logged into your YouTube account, you enable YouTube to assign your surfing behavior directly to your personal profile. You can prevent this by logging out of your YouTube account. YouTube uses cookies and tracking tools. The data processing operations as well as the purposes of the processing can be requested and viewed directly at YouTube.

Contact person:

Markus Schmitz

Carlo Weidemann

https://youtu.be/vYejNjBSUp8

WAAM simulation with ROS in Gazebo

Vincent Brünjes designed a Gazebo plug-in in his master‘s thesis to simulate multidirectional wire+arc additive manufacturing processes.

Contacts:

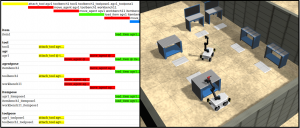

Task planning in industrial scenario

PDDL modeling, ROSPlan and Gazebo simulations are used to improve automatic scheduling algorithms for scenarios with collaborating actors.

Contact person: